Shearing machines are essential in metal fabrication, providing precise and efficient cutting of sheet metal. Whether used in small workshops or large-scale industries, these machines require a significant amount of energy to operate. However, as energy costs rise and industries focus more on sustainability, improving energy efficiency in shearing machines has become crucial.

Energy-efficient machines not only reduce operational expenses but also contribute to environmental conservation. Manufacturers looking to cut down on electricity bills and minimize their carbon footprint need to understand how shearing machines consume power and what steps can be taken to improve efficiency. In this blog, we will discuss why energy efficiency is essential and explore practical ways to reduce power consumption in shearing machines.

Understanding Energy Consumption in Shearing Machines

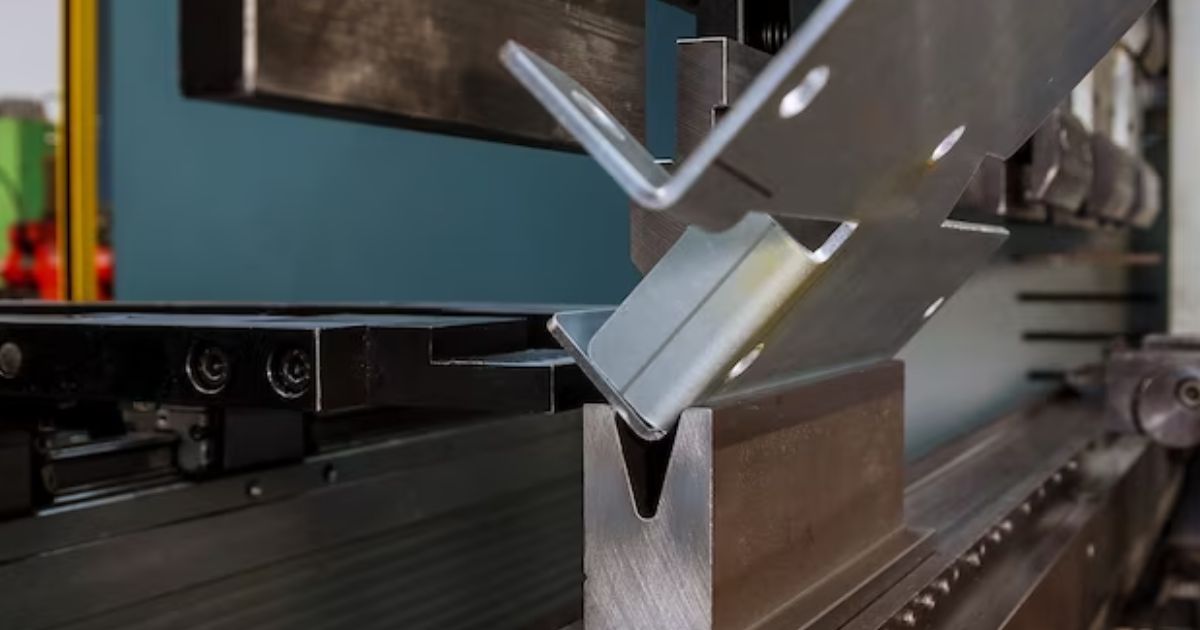

Shearing machines work by applying force through a moving blade to cut metal sheets against a fixed blade. The energy consumption of these machines depends on various factors, including the type of machine, the thickness of the material being cut, and the efficiency of its components.

Different types of shearing machines hydraulic, NC (Numerical Control), and CNC (Computer Numerical Control) have varying energy requirements. Hydraulic shearing machines, for instance, rely on hydraulic pumps that continuously consume power, even when idle. In contrast, CNC shearing machines use advanced control systems that optimize power usage, making them more energy-efficient.

Additionally, the shearing force required to cut different metals affects energy consumption. Cutting thick or hard materials demands more power, while softer metals require less force. Factors like blade sharpness, machine maintenance, and automation also play a role in determining overall energy efficiency.

Why Energy Efficiency Matters in Shearing Machines

1. Cost Savings

One of the most significant benefits of energy-efficient shearing machines is cost reduction. Machines that consume excessive power increase electricity bills, leading to higher production costs. By optimizing energy use, manufacturers can save money and improve their profit margins.

2. Environmental Impact

Industries worldwide are focusing on reducing their carbon footprint, and metal fabrication is no exception. Energy-efficient machines lower greenhouse gas emissions by consuming less electricity, contributing to a cleaner environment. Companies adopting sustainable practices also enhance their reputation and meet regulatory compliance more easily.

3. Extended Machine Lifespan

Shearing machines that operate efficiently experience less wear and tear. Overloading a machine with excessive power consumption can lead to overheating, increased maintenance needs, and shorter equipment life. Optimizing energy use ensures smooth operation and reduces the frequency of costly repairs.

4. Improved Productivity

When energy-efficient machines operate at optimal performance, they produce faster and more precise cuts with minimal downtime. This efficiency allows manufacturers to meet production demands without excessive energy waste, leading to increased productivity.

Key Features of Energy-Efficient Shearing Machines

Modern shearing machines incorporate advanced technology to improve energy efficiency. Some of the most effective features include:

- Variable Speed Drives (VSDs): These control motor speed, reducing unnecessary energy use.

- Servo-Driven Hydraulic Systems: These only consume power when needed, unlike traditional hydraulic systems that run continuously.

- Automated Power-Saving Modes: CNC shearing machines automatically enter standby mode when not in use.

- Optimized Blade Gap Adjustment: Adjusting the blade gap based on material thickness minimizes excess power consumption.

- High-Strength Lightweight Materials: Machine components made from lightweight, durable materials reduce friction and energy loss.

How to Reduce Power Consumption in Shearing Machines

Choosing the Right Machine for Your Needs

Different types of shearing machines have different energy efficiencies. CNC shearing machines are often the best choice for those looking to reduce power consumption, as they feature automated control systems that optimize energy use. Hydraulic shearing machines, while powerful, should be equipped with energy-efficient components like servo-driven pumps to minimize waste.

Regular Maintenance and Lubrication

A poorly maintained machine consumes more energy due to increased resistance and inefficiencies. Regular lubrication reduces friction between moving parts, ensuring smooth operation and lower power usage. Keeping the blades sharp also reduces the force needed for cutting, further enhancing efficiency.

Optimizing Cutting Parameters

Setting the right cutting speed, blade gap, and shearing force ensures that the machine operates with minimal energy waste. Cutting thin sheets at high speeds without overloading the motor helps prevent excess power consumption. Additionally, adjusting the blade gap based on material thickness improves precision while reducing energy loss.

Upgrading to Energy-Efficient Components

Replacing standard motors with high-efficiency motors significantly reduces electricity consumption. Hydraulic shearing machines can also benefit from variable displacement pumps, which adjust power usage based on demand instead of running continuously at full capacity.

Reducing Idle Time and Standby Power Consumption

Many machines consume power even when not actively cutting. Implementing automatic shut-off features and smart control systems can help reduce energy waste. Using motion sensors to detect when the machine is in use and switching it to low-power mode when idle can further optimize efficiency.

Using Renewable Energy Sources

Factories and workshops that rely on shearing machines can further cut costs by integrating solar panels or other renewable energy sources. This approach not only reduces electricity bills but also makes operations more sustainable in the long run.

The Future of Energy-Efficient Shearing Machines

As technology advances, the next generation of shearing machines is expected to incorporate AI-driven automation and self-regulating energy systems. Smart sensors will optimize power usage in real-time, reducing unnecessary consumption while ensuring precise cutting. Additionally, Industry 4.0 innovations will enable seamless connectivity between machines, allowing for better energy management across production lines.

Future shearing machines will likely feature predictive maintenance capabilities, where built-in monitoring systems detect inefficiencies before they lead to excessive power use. These advancements will help manufacturers achieve greater cost savings and sustainability while improving overall productivity.

Conclusion

Energy efficiency in shearing machines is no longer just an option—it is a necessity. By optimizing power consumption, manufacturers can reduce operational costs, lower their environmental impact, extend machine lifespan, and improve productivity. Implementing the right strategies, such as regular maintenance, upgrading to energy-efficient components, and reducing idle time, ensures that shearing machines operate with maximum efficiency.

If you are looking for a high-performance, energy-efficient shearing machine, Energy Mission offers cutting-edge solutions tailored to your needs. Contact us today to explore our range of shearing machines and find the perfect fit for your business!