Horizontal

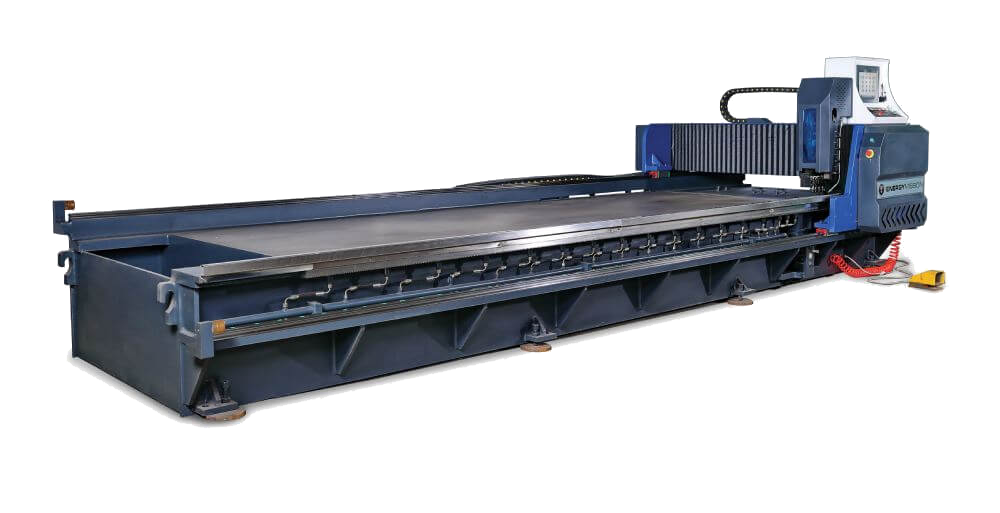

The Hydraulic CNC Bending Machine is a cutting-edge solution designed for precision metal bending in various industrial applications. This versatile machine features advanced CNC synchro hydraulic press brake machine technology, allowing for accurate bends and complex shapes with ease. Its user-friendly controls ensure seamless operation, while the robust construction guarantees durability and reliability. The CNC synchro press brake machine enhances productivity by providing consistent results, making it an essential tool for any workshop focused on high-performance metal fabrication.

- Fast, precise & accurate V grooving

- Machine structure is made from Ultrasonically & tensile tested IS:2062 grade steel to ensures the rigidity

- Large table to easy working. The working area is max. 1.5 meter wide & up to 4.0 meter long

- 4 axis CNC controller with 15” Touch screen & graphics

- Finger profiling is possible

- Possible to V Groove in embossed plate

- Uses Servo Motor, Ball Screw and LM Guide to ensure high accuracy

- Rack & Pinion is used for High Speed & Precise positioning

- Hydraulic clamps to ensure rigid clamping of work piece

- Carriage of Four single point cutting tools, The cutting amount is evenly distributed, reducing deformation of the machined part

- Air gun for removing metal chips from table