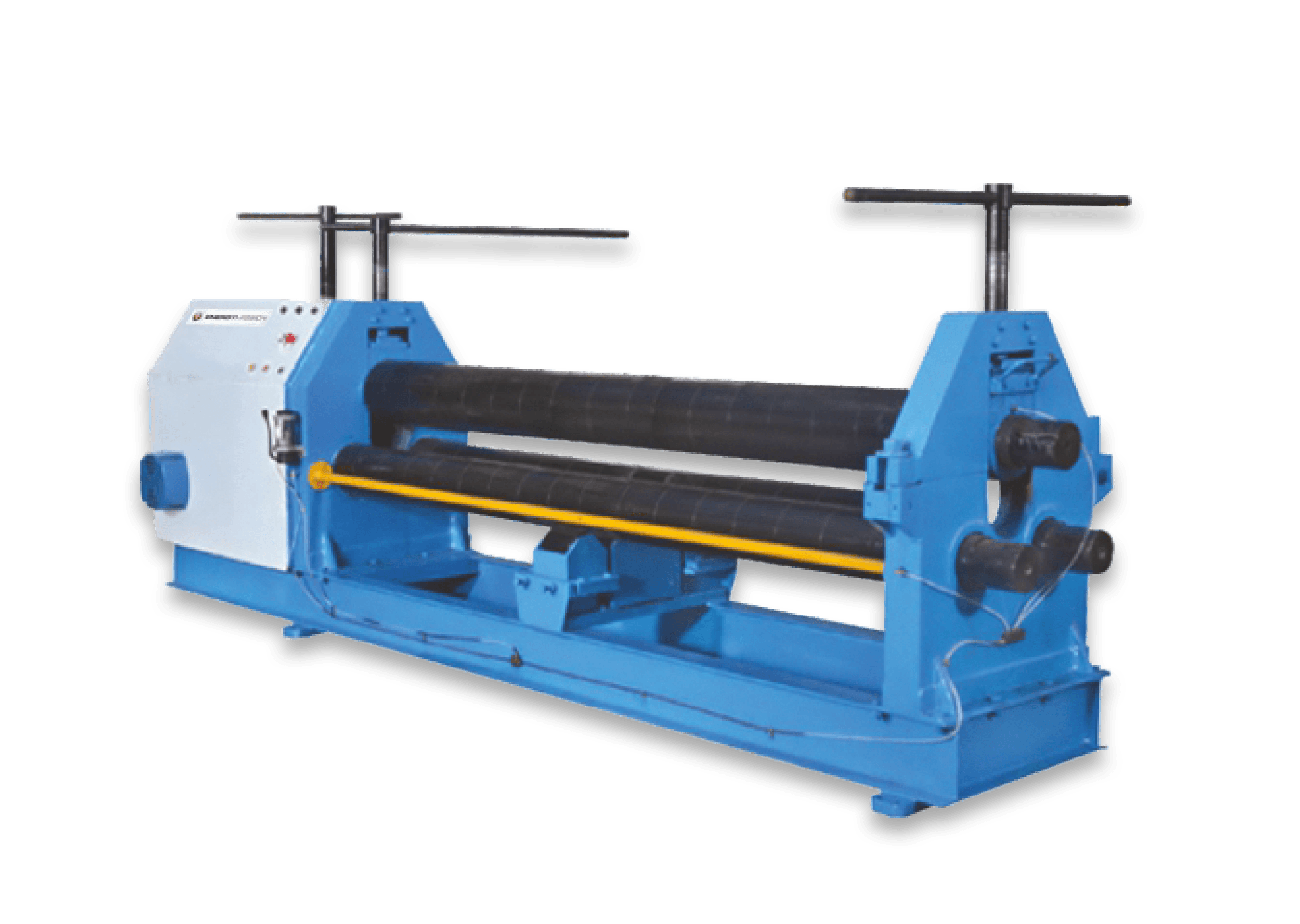

3-Roll Mechanical Series Plate Rolling Machines

Welcome to Energy Mission, a leading plate rolling machine manufacturer and plate rolling machine supplier, offering the robust 3-Roll Mechanical Series for precision, durability, and cost-effective performance. Our plate rolling machines for sale, specifically the 3 roll plate rolling machine and 3 Roll Pyramid Type Rolling Plate Bending Machine, are engineered to meet the needs of industries like construction, aerospace, automotive, shipbuilding, and energy. Whether you require a CNC plate rolling machine, a heavy-duty plate rolling machine, or a manual plate rolling machine, our Hydraulic Plate Bending Machine options within the series deliver reliable performance for shaping metal sheets into cylindrical, conical, or curved forms. Learn about the plate rolling machine specifications, plate rolling machine capacity, and plate rolling machine price to find the ideal equipment for your operations. For advanced automation and precision, check out our 4-roll plate rolling machines for enhanced rolling capabilities.

Why Choose the 3-Roll Mechanical Series Plate Rolling Machines?

The 3-Roll Mechanical Series, including the 3 Roll Pyramid Type Double Pre Pinch Plate Rolling Machine, is designed for simplicity and reliability, offering a cost-effective alternative to four-roll plate rolling machines. The 3 roll plate rolling machine features a pyramid configuration with bottom rolls driven by an electric motor and gearbox, while the top roll is manually adjusted via a screw jack to achieve the desired bending radius, making it ideal for light to medium jobs. Here’s what makes the 3-Roll Mechanical Series stand out:

- Precision Engineering: The CNC plate rolling machine option integrates advanced computer numerical control systems, enabling programmable operations for accurate bending, ideal for complex designs and high-volume production.

- Robust Construction: Built as a heavy-duty plate rolling machine, the series uses welded high-strength steel frames (UT-tested IS:2062 M.S. plates) and alloy steel rollers to handle tough materials like stainless steel, ensuring durability.

- Versatility: From stainless steel plate bending machines to sheet rolling machines for thinner materials, the 3-Roll Mechanical Series supports a wide range of applications, making it ideal for industrial plate rolling machines.

- Cost-Effectiveness: The mechanical design and manual plate rolling machine options offer competitive plate rolling machine price points, perfect for businesses seeking affordability without compromising quality.

- Efficient Pre-Pinching: The 3 Roll Pyramid Type Double Pre Pinch Plate Rolling Machine allows pre-pinching on both ends via bottom rolls driven by hydraulic cylinders, reducing flat ends and improving efficiency.

For specialized section forming, our section bending machines offer robust solutions for angles, channels, and beams.

Our 3-Roll Mechanical Series Plate Rolling Machines for Sale

Energy Mission offers a comprehensive range of plate rolling machines for sale in the 3-Roll Mechanical Series, designed to deliver exceptional performance across industries. Whether you’re shaping stainless steel plate bending machine components for chemical processing or medium plates for shipbuilding, the 3-Roll Mechanical Series provides unmatched plate rolling machine capacity and flexibility. Below, we outline the key features and benefits of this equipment.

Key Features of the 3-Roll Mechanical Series

The 3 roll plate rolling machine in the 3-Roll Mechanical Series is equipped with features to ensure top performance:

- High-Capacity Rollers: The series offers robust plate rolling machine capacity, handling sheet thicknesses from thin gauges to medium plates up to 40 mm, depending on the model.

- CNC Control Options: Our CNC plate rolling machines feature user-friendly interfaces and programmable settings, ensuring precise, repeatable results with minimal operator training.

- Mechanical Drive System: Bottom rolls are driven by an electric motor and gearbox, providing reliable power for heavy-duty plate rolling machines in industrial settings.

- Safety Features: Includes emergency stop systems, overload protection, and operator safety guards for a secure working environment.

- Double Pre-Pinch Design: The 3 Roll Pyramid Type Double Pre Pinch Plate Rolling Machine enables pre-pinching on both ends, completing the shell in multiple operations for enhanced productivity.

For precise tube forming, our tube bending machines deliver accurate pipe and tube shaping.

Alt text: Tube Bending Machine for precision pipe forming

Applications of the 3-Roll Mechanical Series Plate Rolling Machines

The 3 roll plate rolling machine in the Mechanical Series is designed for a wide range of applications, making it essential for industries requiring precise metal forming. Key applications include:

- Construction: Shaping curved metal components for bridges, tunnels, structural beams, and architectural facades using industrial plate rolling machines.

- Aerospace: Producing precision parts for aircraft fuselages, wings, and spacecraft components with CNC plate rolling machines for tight tolerances.

- Automotive: Forming exhaust systems, chassis components, and body panels with sheet rolling machines for consistent quality.

- Energy: Manufacturing components for pipelines, pressure vessels, wind turbine towers, and solar panel frames, leveraging stainless steel plate bending machine capabilities.

- Shipbuilding: Rolling plates for ship hulls, decks, and offshore platforms with heavy-duty plate rolling machines.

- Chemical Processing: Shaping corrosion-resistant materials like stainless steel for tanks and reactors using stainless steel plate bending machines.

For sheet metal pressing needs, our hydraulic press brakes provide precise bending solutions.

Alt text: Hydraulic Press Brake for accurate sheet metal bending

Why Energy Mission is Your Trusted Plate Rolling Machine Supplier

As a leading plate rolling machine manufacturer and plate rolling machine supplier, Energy Mission is committed to delivering high-quality equipment backed by exceptional service. Here’s what sets us apart:

- Industry Expertise: With over 25 years of experience in sheet metal processing machinery, we understand the unique challenges of each industry and provide tailored solutions.

- Quality Assurance: Every plate rolling machine undergoes rigorous testing to meet international standards (ISO 9001:2015 certified) for performance, safety, and durability.

- Comprehensive Support: From installation and operator training to ongoing maintenance, our team ensures your Hydraulic Plate Bending Machine operates at peak performance, with service centers across India, including Ahmedabad, Mumbai, and Chennai.

- Competitive Pricing: We offer plate rolling machines for sale at competitive plate rolling machine price points, ensuring excellent value for your investment.

- Global Reach: Serving clients worldwide, including UAE, Oman, and Kenya, we provide timely delivery and support for all our industrial plate rolling machines.

Benefits of Investing in the 3-Roll Mechanical Series

Investing in a 3 roll plate rolling machine from Energy Mission’s Mechanical Series offers numerous advantages:

- Increased Productivity: The double pre-pinch design reduces setup time and material handling, enabling faster production cycles compared to four-roll plate rolling machines.

- Cost Savings: Energy-efficient mechanical systems and durable construction minimize maintenance and operational costs, optimizing your plate rolling machine price investment.

- Superior Precision: The CNC plate rolling machine option ensures accurate, repeatable results, reducing material waste and rework.

- Versatility: Suitable for a wide range of materials and thicknesses, from thin sheets to medium plates, making it a true sheet rolling machine and heavy-duty plate rolling machine.

- Scalability: The 3-Roll Mechanical Series is designed to grow with your business, offering flexibility for both small and large-scale projects.

For smaller-scale operations, our manual plate rolling machines offer cost-effective solutions.

How to Choose the Right 3-Roll Plate Rolling Machine

Selecting the right plate rolling machine depends on several factors:

- Material and Thickness: Determine the type (e.g., stainless steel, aluminum) and thickness of materials to choose a machine with adequate plate rolling machine capacity.

- Production Volume: High-volume operations benefit from CNC plate rolling machines, while smaller workshops may prefer manual plate rolling machines for cost-effectiveness.

- Application Needs: Consider whether you need to produce cylindrical, conical, or multi-radius shapes, and select a machine with the appropriate plate rolling machine specifications.

- Budget: Balance your budget with the features you need, keeping in mind our competitive plate rolling machine price offerings.

- Space Constraints: Ensure the machine fits your facility, especially for compact manual plate rolling machines or larger industrial plate rolling machines.

Our team at Energy Mission is available to guide you through the selection process, ensuring you find the ideal 3 Roll Pyramid Type Rolling Plate Bending Machine for your needs.

Technical Specifications of the 3-Roll Mechanical Series

The plate rolling machine specifications for the 3-Roll Mechanical Series are designed to meet diverse industrial needs, particularly for light to medium jobs. Below is a detailed specification table based on industry standards for 3 Roll Pyramid Type Rolling Plate Bending Machine and Energy Mission’s product descriptions:

| Specification | Details |

| Machine Type | 3 Roll Pyramid Type Double Pre Pinch Plate Rolling Machine (Mechanical) |

| Roller Diameter | 100 mm to 400 mm (model-dependent) |

| Working Width | 1,000 mm to 3,000 mm |

| Maximum Plate Thickness | Up to 40 mm (based on normal steel with yield point 260 N/mm²) |

| Material Compatibility | Steel, stainless steel, aluminum, and other alloys |

| Motor Power | 3 HP to 30 HP (electric motor with gearbox, model-dependent) |

| Control System | Manual or CNC plate rolling machine configurations |

| Pre-Bending Capacity | Up to 30 mm (model-dependent, for stainless steel plate bending machine) |

| Bending Radius | Minimum diameter 2x top roll diameter (dependent on plate thickness) |

| Drive System | Bottom rolls driven by electric motor and gearbox |

| Safety Features | Emergency stop, overload protection, operator safety guards |

| Frame Construction | Welded high-strength steel (IS:2062 M.S. plates, UT-tested) |

| Surface Treatment | Epoxy zinc-rich primer (30 µm), alkyd acid topcoat (160 µm, RAL7011/7035) |

| Automation Level | Manual (manual plate rolling machine) or CNC |

| Applications | Cylindrical, conical, and multi-radius shapes for light to medium jobs |

| Additional Features | Manual top roll adjustment via screw jack, optional conical bending |

Find Your Ideal Plate Rolling Machine Today

Ready to enhance your metal forming capabilities? Check out the 3-Roll Mechanical Series at Energy Mission and find the perfect plate rolling machine for sale for your business. Whether you need a CNC plate rolling machine for automated precision, a heavy-duty plate rolling machine for robust applications, or a manual plate rolling machine for smaller projects, our 3-Roll Mechanical Series has you covered. For additional options, visit our 4-roll plate rolling machines, tube bending machines, or hydraulic press brakes.

Contact us today to learn about our industrial plate rolling machines, request detailed plate rolling machine specifications, or get a personalized plate rolling machine price quote. Our experts are ready to help you select the right stainless steel plate bending machine or sheet rolling machine to boost productivity and achieve superior results.