Sheet metal fabrication is a driving force in industries such as automotive, construction, aerospace, and manufacturing, where precision and efficiency are critical for producing high-quality components. The hydraulic shearing machine is a pivotal tool in this process, delivering clean, accurate cuts across a variety of metal types. From hydraulic guillotine shearing machines to small hydraulic shearing machines, these tools offer versatile solutions tailored to businesses of all scales. Leading hydraulic press machine manufacturers, particularly in regions like India, produce advanced equipment, including CNC press brake machines and hydraulic punching and shearing machines, that meet global standards. This comprehensive guide explores the features, benefits, and leading hydraulic press brake machine suppliers in India, focusing on hydraulic shearing cutting machines and their applications to help businesses select the best tools for their fabrication needs.

What Is a Hydraulic Shearing Machine?

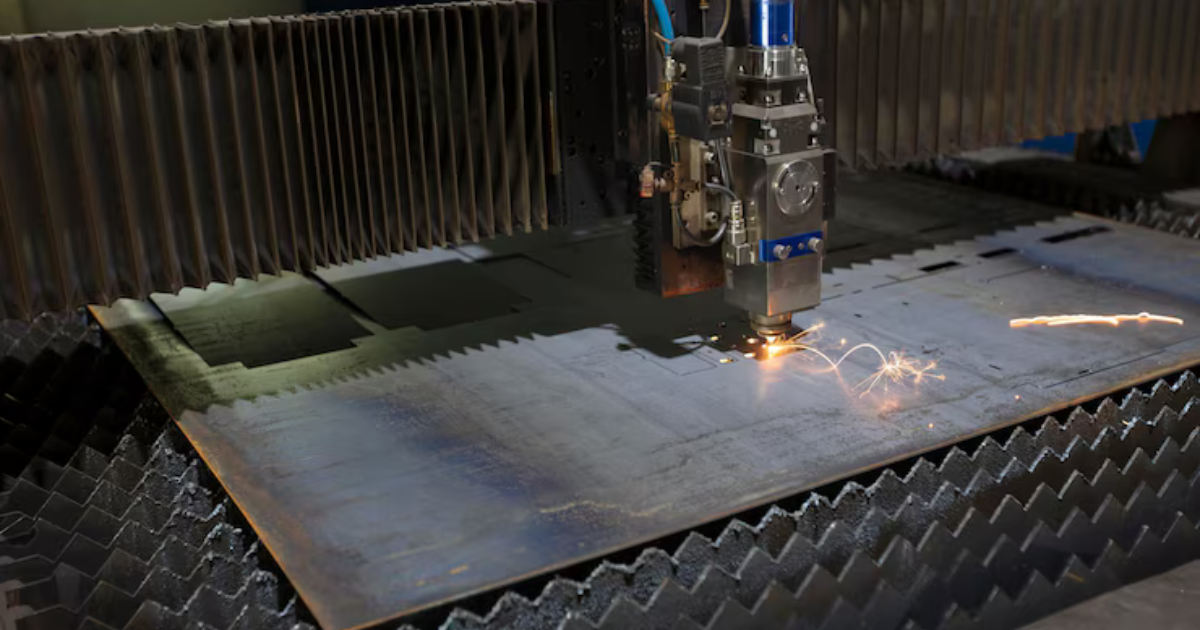

A hydraulic shearing machine is an industrial tool that harnesses hydraulic power to cut metal sheets, plates, and bars with exceptional precision. By driving a moving blade against a fixed one, these machines produce clean, straight cuts with minimal material waste. They are designed to process materials like mild steel, stainless steel, and aluminum, serving industries that demand high-volume cutting. For instance, hydraulic guillotine shearing machines, such as those from Hindustan Hydraulics in India, feature a guillotine-style blade for enhanced cutting accuracy. Modern models incorporate numerical control (NC) or computer numerical control (CNC) for programmable settings like blade gap, backgauge position, and cutting speed, which significantly improve efficiency. Constructed with robust steel frames, these machines ensure durability, while safety features like overload protection and emergency stops prioritize operator security.

Key Features of Hydraulic Shearing Machines

- Adjustable blade gap for cutting various material thicknesses.

- High-quality blades (e.g., 6CrW2Si for mild steel) for durability.

- Hydraulic system for smooth, powerful cuts with minimal noise.

Types of Hydraulic Shearing Machines

The versatility of hydraulic shearing machines lies in their diverse configurations, each designed to meet specific fabrication needs. Hydraulic guillotine shearing machines are renowned for delivering straight, precise cuts, making them ideal for large-scale production environments. Small hydraulic shearing machines, such as those from SC SHENCHONG, are compact and cost-effective, perfectly suited for small workshops or spaces with limited floor area. Hydraulic punching and shearing machines combine cutting and punching capabilities, offering multifunctionality for complex fabrication tasks, such as creating holes or slots in metal components. These machines, often equipped with NC or CNC controls, cater to a wide range of applications, from automotive parts to structural steel components. For example, HARSLE’s hydraulic guillotine shears feature fast backgauge systems, achieving cutting speeds of 20-60 times per minute, which significantly boosts productivity.

How Does a Hydraulic Cutting Machine Work?

Understanding hydraulic cutting machine working is key to appreciating its efficiency and precision. The machine operates by using a hydraulic pump to drive a cylinder, which moves the upper blade downward against a fixed lower blade. The hydraulic system, powered by high-quality components from brands like Bosch-Rexroth or Yuken, delivers consistent force, enabling clean cuts without burrs or distortion. Operators can adjust the blade gap and rake angle to suit the material’s thickness, ensuring minimal stress on the metal. Advanced models, like those from Hindustan Hydraulics, integrate NC or CNC controllers, such as ESTUN E21S or Cybelec CybTouch, allowing operators to store cutting programs for repetitive tasks. This automation reduces setup times and ensures precision, making hydraulic shearing cutting machines a reliable choice for high-volume production environments.

Comparing Hydraulic Shearing Machines to CNC Press Brakes

While hydraulic shearing machines specialize in cutting, CNC press brake machines excel at bending metal sheets, making them complementary tools in sheet metal fabrication. CNC press brakes, equipped with advanced controllers like Delem DA66T, offer programmable bending sequences for creating complex shapes, ideal for industries requiring intricate components, such as automotive or electronics. In contrast, hydraulic shearing cutting machines focus on producing straight, clean cuts with adjustable blade gaps and backgauges for accuracy. Manufacturers like Jayshree Machinetools in India produce both types, with servo electric press brakes providing eco-friendly alternatives to hydraulic systems, reducing energy costs and environmental impact. Combining these machines enables workshops to handle a full spectrum of fabrication tasks, from cutting to forming, with maximum efficiency and precision.

Why Hydraulic Press Brake Machines Are Essential

Hydraulic press brake machines enhance fabrication workflows by offering robust bending capabilities that complement shearing operations. Highly valued by hydraulic press brake machine suppliers in India, these machines can handle thick metal sheets with tonnage capacities ranging from 40 to 800 tons. Their hydraulic systems, powered by premium components from Yuken or Rexroth, ensure smooth operation, while synchronized rams and high-resolution linear scales deliver precise bends. Manufacturers like Maruti Machine Tools in India offer customizable designs, such as front or rear cylinder configurations, to meet specific bending requirements. These machines are more cost-effective than fully electric systems, making them accessible to small and medium enterprises while maintaining high performance for heavy-duty tasks.

Advantages of Hydraulic Press Brake Machines

- High tonnage for bending thick materials with ease.

- Silent operation reduces tool wear and enhances operator safety.

- Customizable configurations for a wide range of bending applications.

Leading Manufacturers in India

India is a global hub for hydraulic press machine manufacturers and hydraulic press brake machine manufacturers in India, recognized for their innovation and commitment to quality. Hindustan Hydraulics, based in Punjab, brings over 25 years of experience, offering hydraulic guillotine shearing machines and press brakes with synchronized bed reference technology for precise cuts and bends. Jayshree Machinetools in Rajkot, Gujarat, specializes in eco-friendly servo electric press brakes and small hydraulic shearing machines, emphasizing sustainability and high-quality materials. Maruti Machine Tools, also in Rajkot, uses premium components from Yuken and Rexroth, ensuring compliance with international standards. Pusaan Automation Pvt. Ltd. provides automated NC and CNC solutions, focusing on cost-effective performance. Ravi Industrial Corporation in Delhi manufactures eco-friendly hydraulic punching and shearing machines for global export, supported by rigorous quality checks. These manufacturers offer comprehensive after-sales support, ensuring long-term reliability and customer satisfaction.

Leading Manufacturers to Explore

- Hindustan Hydraulics: Precision guillotine shears and press brakes.

- Jayshree Machinetools: Eco-friendly servo electric and small shears.

- Maruti Machine Tools: Durable hydraulic machines with premium components.

Choosing the Right Hydraulic Shearing Machine

Selecting the ideal hydraulic shearing machine involves aligning the equipment with your operational requirements. Start by considering the material type and thickness, ensuring the machine’s capacity matches your needs, such as mild steel up to 20 mm thick. For high-volume cutting, prioritize models with fast backgauge systems and high cutting speeds, like SC SHENCHONG’s QC11Y series, which achieves speeds up to 60 cuts per minute. Evaluate automation needs—NC or CNC controllers like Cybelec CybTouch enhance efficiency for complex or repetitive tasks. Budget is a critical factor; hydraulic press brake machine manufacturers in India offer competitive pricing, but prioritize those with strong after-sales support, like HARSLE, which provides detailed manuals and spare blades. Finally, ensure the machine’s footprint and power requirements are compatible with your workshop’s infrastructure to avoid operational challenges.

The Future of Sheet Metal Fabrication

The sheet metal fabrication industry is advancing rapidly, fueled by innovations from hydraulic press machine manufacturers. High-speed hydraulic shearing cutting machines, such as those from SC SHENCHONG, minimize blade wear and enhance accuracy with cutting speeds 10-20 times faster than standard models. Industry 4.0 technologies, like IoT-enabled machines, enable real-time monitoring and predictive maintenance, reducing downtime and improving efficiency. Sustainability is a growing priority, with manufacturers like Jayshree Machinetools developing oil-free servo electric systems to lower environmental impact. These advancements, particularly from Indian manufacturers, position the region as a global leader in fabrication equipment, offering businesses cutting-edge solutions to stay competitive in a dynamic market.

Emerging Trends in Fabrication

- High-speed hydraulic shearing for enhanced productivity and blade longevity.

- IoT integration for smart monitoring and predictive maintenance.

- Eco-friendly servo electric systems for sustainable manufacturing.

Maximizing Hydraulic Shearing Machine Performance

To optimize the performance of your hydraulic shearing machine, regular maintenance is essential. Routinely inspect hydraulic fluid levels, blade sharpness, and electrical systems to prevent unexpected downtime. Train operators on NC or CNC programming and safety protocols to improve efficiency and minimize errors. Use high-quality blades, such as SC SHENCHONG’s 6CrW2Si for mild steel or Cr12MoV for stainless steel, to extend service life and maintain cut quality. Keep controllers updated to leverage the latest features, ensuring consistent, high-quality cuts. These practices not only maximize equipment lifespan but also deliver reliable, cost-effective results for your fabrication operations.

Conclusion

Hydraulic shearing machines, including hydraulic guillotine shearing machines, small hydraulic shearing machines, and hydraulic punching and shearing machines, are transforming sheet metal fabrication with their precision and versatility. With leading hydraulic press brake machine suppliers in India like Hindustan Hydraulics, Jayshree Machinetools, Maruti Machine Tools, Pusaan Automation, and Ravi Industrial Corporation, businesses have access to world-class equipment tailored to their needs. Whether cutting thick plates or performing complex punching tasks, these hydraulic shearing cutting machines deliver exceptional performance. Contact a trusted hydraulic press machine manufacturer today to explore their range and elevate your fabrication process to new heights.